Industry Standard Measurement Tools in HoloLens

Microsoft dynamics 365 Layout

HoloLens & VR

Across all industries transformation is key to growth and designing new spaces involves detailed planning. If you aren’t prepared, the smallest oversight can cause costly delays. Microsoft Dynamics 365 Layout is a product across HoloLens and VR–it helps you plan your space, collaborate with others, and experience your designs with confidence in mixed reality before you build. But even with the most detailed planning, the real world can present unexpected challenges that require creative problem-solving. Spatial measuring tools help you design and review with precision and give you confidence before you commit.

In this project, you will see some highlights of how spatial measurement evolved from an idea to a confidence-inspiring shipping product that helped to validate and design improved safety protocols.

High-level Impact:

Increased subscriptions and HoloLens device sales by developing a series of spatial measurement tools that enabled enterprise customers to leverage HoloLens devices to perform high-precision industrial measurement as part of space planning and to validate and design improved safety protocols.

The spatial measurement tools unblocked a large-scale purchase of HoloLens by Toyota.

Leveraged product learnings to proactively influence peer organizations’ product roadmap.

Early Ideation

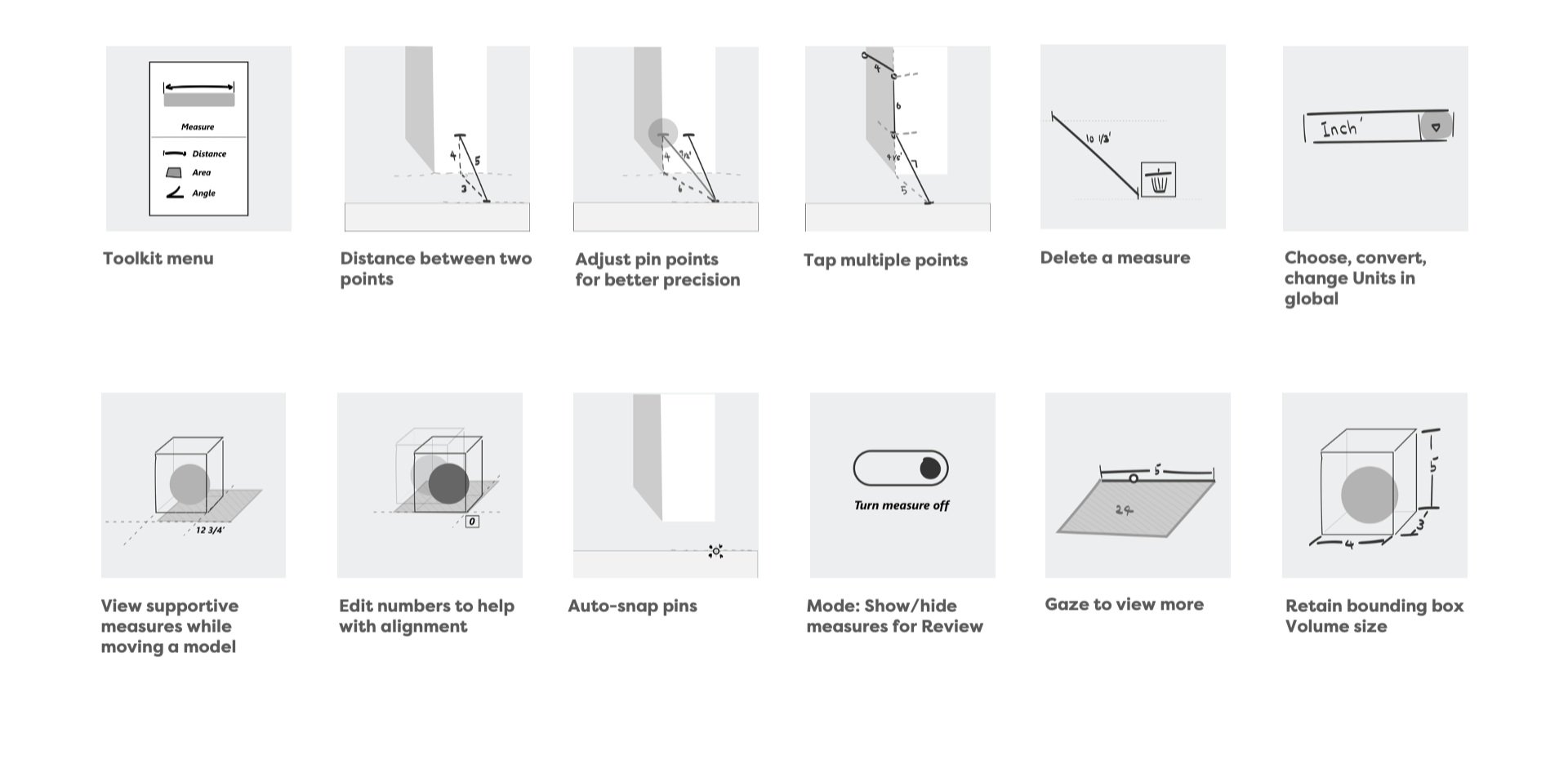

Time and time again, customers requested measurement tools in interviews. With the limited research data we have, I sketched out some quick ideation to capture my instincts. This is an approach we use a lot on Mixed Reality teams—we can explore without fear, generate quick ideas, and start conversations with people.

I did Parallel Research to find real-world parallels and competitors.

Key learnings were generated to help scope ideas and converge options.

I worked with a prototyper and the engineering team on interactive prototypes, so we could spot the gaps in the experience and get feedback from customers.

We took the prototype in the UR test and hired people who are not working in the MR industry to test out the experience assuming most customers are frontline workers unfamiliar with these technologies and interactions. Insights from the UR study helped drive our design excellence.

We released Measurement V1 as a collaborative effort across design, research, engineering and PM!

The release got great feedback from major customers and attracted new customers, and we got so many new requests about measuring tools! The feature got secured funding, and scaled up from one engineer to seven, enabling us to keep bringing value to customers and the product.

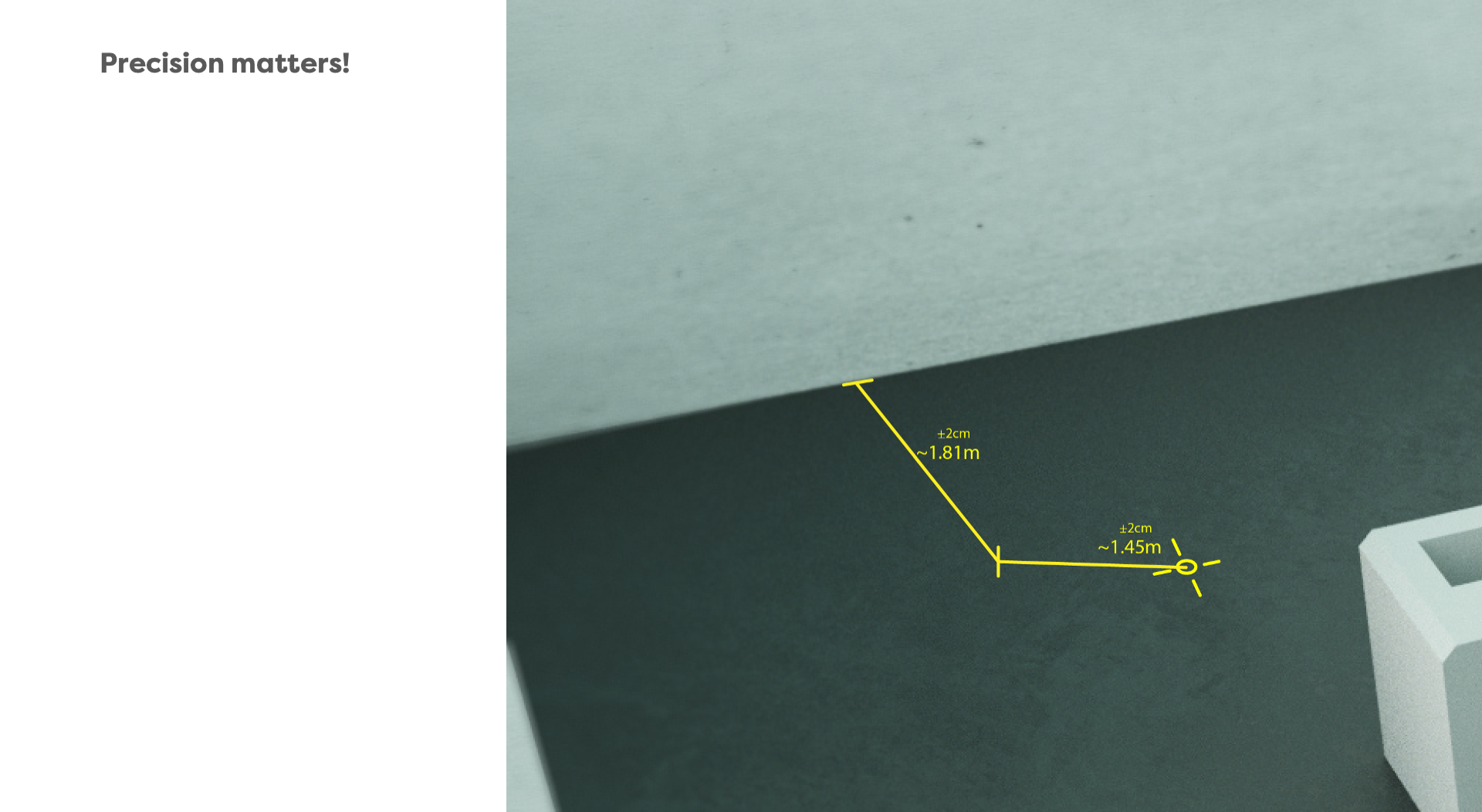

Our goal is to deliver the highest standard measuring tools and precision matters! We explored how we can increase precision with gestures and behaviors, spatial understanding, and visual guidance. Below is an example of how we empower precise measurement by auto-snapping the endpoints.

And we shipped monthly updates!

Working with seven engineers simultaneously required a strategic approach to bring everyone in & align with their passion and skillset. I learned much about how to work with different personalities, accelerate them, and build deep and enduring partnerships.

Also, I committed to bringing clarity. Below is an example of how I delivered guidance.

We prioritized designing for HoloLens and then customized the experience for VR. Customers are empowered to design in VR and then bring their design into the real world in AR.

We did a series of customer engagements while building the feature, from weekly customer calls to customer onsite visits, where we could feel their environment and they could try out the Hololens. With the released spatial measuring tools, we unblocked major customers like Toyota and ZF with their precision requirements for collision testing, space planning, and more. I would love to chat more about these customer stories in person, they were so exciting!

We took customer feedback, placed it in the problem space, and generalized it to apply throughout the app.

With team passion, customer love, time, and the resources we earned, we aimed for excellence instead of just a minimum viable product!

We ran competitor analysis and aimed to pitch for building the highest possible precision to hit industry standards on HoloLens, future MR devices, and mobile. We pitched the idea and execution plan to peer organizations and influenced their roadmap.

Learnings:

How to differentiate the root problem from the perceived/articulated customer problems.

How to tailor my approach in working with a very diverse set of personalities and to make sure everyone felt a sense of ownership. Soften my ego in order to achieve collective objectives.

r